Filling & Closing

-

Read more

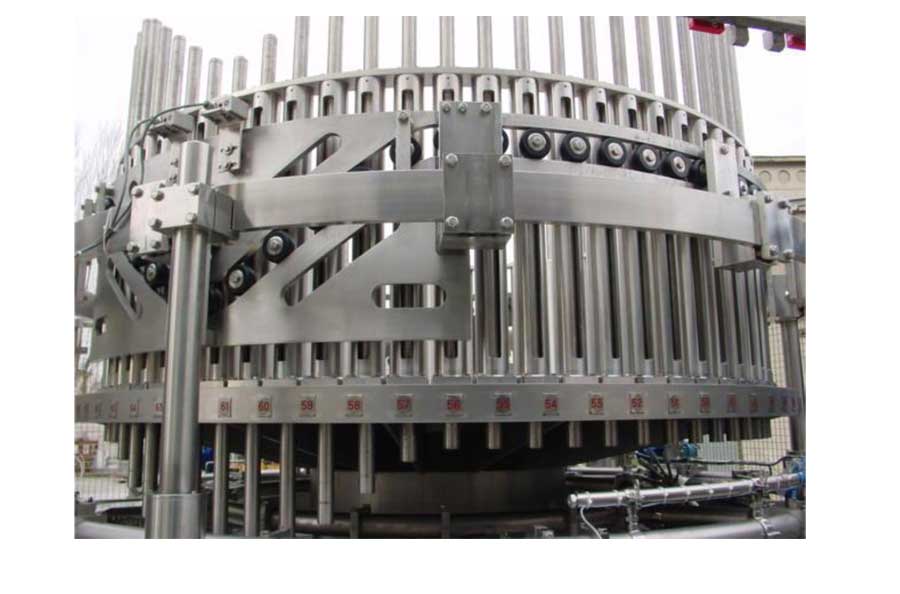

Automatic Telescopic And Semitelescopic Fillers

Zilli & Bellini telescopic and semi-telescopic fillers are suitable to handle a wide range of products, from free-flowing granular products to whole peeled tomatoes.

With this machine, we transfer exactly the volume of product that we want into the containers.

CONTAINERS

The machines can handle round and non-round metal, glass, plastic and composite containers having a filling capacity up to 5 KgCAPACITY

From 10 to 2500 c. p. m. according to the product and container size.AUTOMATIC CLEANING SYSTEM (C.I.P.)

Zilli & Bellini can provide, as an option, a system for the automatic cleaning of the fillerPRODUCTS

- peeled tomatoes (whole, sliced and diced)

- olives (whole and sliced)

- mushrooms (whole and sliced)

- pet food

- pulses: peas, chick-peas, lentils, beans and broad beans

- vegetables (whole, sliced and diced): carrots, potatoes, onions, corn kernels, green beans, etc.

- fruits (whole, sliced and diced): cherries, strawberries, plums, gooseberries, apricots, pears, peaches, etc.

- ravioli, pasta, cereals and rice

- cockles and mussels

- peanuts

Quick View -

Read more

Containers Types

Zilli & Bellini’s core business is providing filling and closing lines for rigid containers: tin plate or aluminium cans, plastic containers, glass containers, composite containers.

The containers can be round or shaped with different kind of covers according to the Customer’s specifications. The container volume can be up to 5 Kg.

New kinds of container can be tested in our laboratories using our prototypes.

The production and installation of filling and closing lines for food products has been our job for over 50 years. We are proud to have the best food companies around the world in our reference list.Quick View -

Read more

Filling And Seaming Groups For Aluminium And Tin Plate Cans

Zilli & Bellini filling and seaming groups are suitable to fill and seam food products or flat soft drinks in tin plate and aluminium cans.

The advantage of the filler – seamer group is the mechanical synchronization, with only one drive, which can smoothly drive the filled containers to the seamer without spillage.

CONTAINERS

The fillers seamers groups can handle round tin plate or aluminium cansCOVERS

The seamers can handle open top, easy open and easy peel lidsCAPACITY

From 10 to 1200 c. p. m. according to the product and container size.AUTOMATIC CLEANING SYSTEM (C.I.P.)

Zilli & Bellini can provide, as an option, a system for the automatic cleaning of the groupsPRODUCTS

It is possible to fill from liquid to very dense products with or without pieces.MODELS

Several models are available based on the speed, size and product.Quick View -

Read more

Handpack Fillers

Zilli & Bellini handpack fillers are suitable to handle a wide range of products, from olives to whole peeled tomatoes.

The machines are suitable for the total filling of containers sometimes automatically sometimes with the help of the operators.CONTAINERS

The machines can handle round and non-round metal, glass, plastic and composite containers having a filling capacity up to 5 Kg

CAPACITY

From 10 to 500 c. p. m. according to the product and container size.

AUTOMATIC CLEANING

Zilli & Bellini can provide, as an option, a system for the automatic cleaning of the filler

PRODUCTS

- whole peeled tomatoes

- whole olives

- whole mushrooms

- whole vegetables

- vegetable cocktails

- whole fruits

- fruits cocktails

Quick View -

Read more

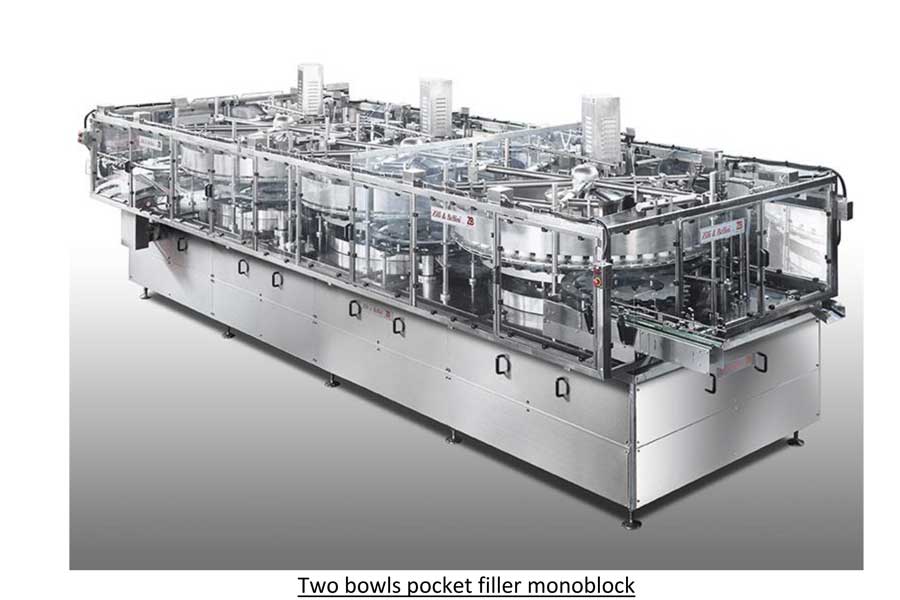

Monoblocks

Zilli & Bellini monoblocks are suitable to fill and close food products or flat soft drinks in round or shaped bottles made of glass and plastic materials.

The idea of the monoblock is to have more than one station installed in the same base frame: in this way it is possible to have an integrated system to clean, fill and close the containers.

One of the advantages of this solution is that the containers, after the filling phase, are moved in a synchronized monoblock in order to eliminate spillage of the product before the closing phase. We also eliminate any damage of the packaging.

A precisely timed drop of liquid Nitrogen (NL2) can be dosed into the headspace.

CONTAINERS

The monoblocks can handle round or shaped bottles made of glass and plastic materials.COVERS

The capping turret can close different kinds of cover made from different kinds of material in accordance with the Customer’s specificationsCONTAINER CLEANING

The empty containers can be cleaned with different kinds of cleaning media in accordance with the Customer’s specifications.CAPACITY

From 10 to 1200 c.p.m. according to the product and container size.PRODUCTS

It is possible to fill from liquid to very dense products with or without pieces.AUTOMATIC CLEANING SYSTEM (C.I.P.)

Zilli & Bellini can provide a system for the automatic cleaning of the monoblockMODELS

Several models are available based on the speed, size and product.Quick View -

Read more

Monoblocks For Ultraclean Filling

The monoblock is an integrated system to perform every phase in a controlled environment. All the processes are done in an area where there is an overpressure of sterile air (LAMINAR FLOW). In the upper part of the monoblock there is a stainless steel cover supported by the safety guards in order to reduce contamination coming from the outside during the critical processes of cleaning, filling and closing. A system of high efficiency HEPA filters introduce sterile air into the machine. After the filling phase, the containers are moved inside a synchronized monoblock without any product spillage before and during the closing phase.

A precisely timed drop of liquid Nitrogen (NL2) can be dosed into the headspace.CONTAINERS

The monoblocks can handle round or shaped bottles made of glass or plastic.COVERS

The capping turret can close different kinds of cover made from different kinds of material in accordance with the Customer’s specificationsCONTAINER AND COVER SANITIZING

The empty containers and the covers can be sanitized with different kinds of cleaning media in accordance with the Customer’s specifications.CAPACITY

From 10 to 1200 c. p. m. according to the product and container size.PRODUCTS

It is possible to fill from liquid to very dense products with or without pieces.AUTOMATIC CLEANING SYSTEM (C.I.P.)

Zilli & Bellini can provide a system for the automatic cleaning of the monoblockMODELS

Several models are available based on the speed, size and product.Quick View -

Read more

Multifillers

Zilli & Bellini multi-fillers are suitable to handle fruit cocktail, fruit salad and vegetable salads.

CONTAINERS

The machines can handle round and non-round metal, glass, plastic and composite containers having a filling capacity up to 5 KgCAPACITY

From 10 to 1200 c. p. m. according to the product and container size.AUTOMATIC CLEANING SYSTEM (C.I.P.)

Zilli & Bellini can provide, as an option, a system for the automatic cleaning of the fillerPRODUCTS

- Fruit: cherries, apricots, pears, peaches, grapes, etc. …

- Vegetables: peas, carrots, potatoes, corn kernels, green beans, beans, etc. …

Quick View -

Read more

Powder Fillers

Zilli & Bellini powder fillers are suitable to handle a wide range of powdered and free flowing granulated products.

CONTAINERS

The machines can handle round and non-round metal, glass, plastic and composite containers having a filling capacity up to 5 Kg.CAPACITY

From 10 to 600 c.p.m. according to the product and container size.AUTOMATIC CLEANING SYSTEM (C.I.P.)

Zilli & Bellini can provide, as an option, a system for the automatic cleaning of the fillerPRODUCTS

- Powder with fat content less than 28%.

- Dried granulated product

Quick View -

Read more

Product Feeding Systems

Different systems suitable to feed different kind of solid products to the filler. Constant and proper feeding of the product is the first target to obtain good filling performance.

Quick View